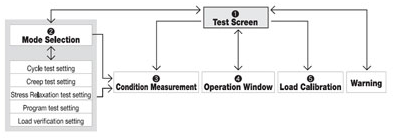

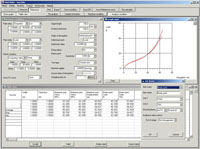

The main window for displaying a graph and starting a test |

Select testing mode |

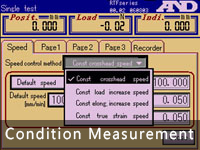

Setting test speed, such as constant crosshead speed and constant load increase speed |

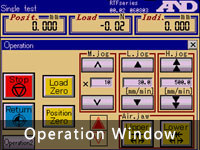

Ultra-fine, fine and coarse adjustments possible |

Simple load calibration with the touch of a button |

|

|

|

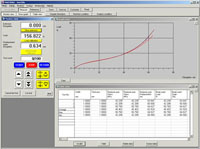

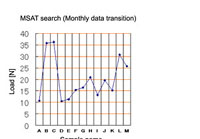

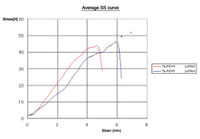

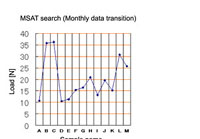

Data processing software

The MSAT series is equipped with functions for not only testing machine operation but also data analysis, calculation and data storage

for each testing mode. The operator can select Standard test (tensile, compression and bending) mode, Peeling test mode, Cycle test

mode, Creep test mode, Stress relaxation test mode etc. depending on the purpose of the test.

PC operation environment OS: Windows XP Professional. Program size: 80Mb or smaller. Memory requirement: 512Mb or over. Authority requirement: Administrator authority. USB: One USB port. Display resolution: 800x600 dots or higher color display .

| Touch Panel | MSAT | Display | Commander | Recorder | |

|---|---|---|---|---|---|

| MSAT | Optional | Standard (Mandatory) |

Optional | Optional | Optional |

Standard layout setting during a measurement

■ Status Display Window, Graph Display Window and Table Display Window |

■ Operation Conditions Window, Sample Information Window, Detailed Conditions Window, Dimension Table Window |

■ Analysis Condition Window, Table Display Window, Arbitrary Formula Window |

■ Reanalysis Window |

Display & Commander

RTF series with user interface for advanced operation

Display

Detachable digital display for load and displacement indication. This display can be attached with magnets to any part of the machine

and it does not obstruct the user when fixing a sample to the jig or testing a sample as its position can be freely adjusted.

| Fixing method | Magnet attachment method |

|---|---|

| Display data | Load/displacement |

| Load | 6-digit indication |

| Displacement | 6-digit indication |

Load

6-digit indication

The indication unit will be automatically selected from kN, N, mN or N.

Displacement

1/1000 display at minimum

The detachable display offers a more organized and efficient workspace.

Commander

Handy compact commander for testing machine control. This commander can be attached to the top, bottom, left or right of the testing machine digital display for load and displacement indication.

The commander’s manual operation buttons are ergonomically designed with bright colors and varied sizes for superior ease-of-use. The jog dial on the right hand side of the commander offers extra flexible control and the operator can move the crosshead up and down by manually rotating this dial.

Applications

A&D's wide range of applied products for even more advanced applications :

Applied test jigs for strength measurement

Screw action jaws  |

Air jaws |

Compression cage |

Wedge action jaws |

Compression test jig |

Compression type bending test jig |

Applied testing devices for elongation measurement

| SG series strain gauge device for measuring distance between gauge marks  |

Non-contact extensometer between gauge marks |

Applications

LOT SET Application |

Excel PU |

Quality control application |

Applied testing devices for temperature / environment test

■ Constant temperature / constant humidity testing devices

■ High temperature testing devices

■ Ultra-low temperature testing devices

■ High humidity in gas atmosphere testing devices

■ High humidity in vacuum testing devices

■ Dipping testing devices

Data Recorder

Analog recorder (AR-6600-7)

This recorder is equipped with a control panel providing easy setup with one-touch zero-span adjustment and auto ranging.

Load frame table

| Dimensions (mm) | |

|---|---|

| RTF-20 for RTF-1310, RTF-1250, RTF-1225 and RTF-1210 | 680(W)x555(D)x630(H) |

| RTF-22 for RTF-1350 and RTF-1325 | 897(W)x650(D)x460(H) |

Recorder table (Wing)

| Dimensions (mm) | |

|---|---|

| RTF-21 for RTF-1350 and RTF-1325 | 420mm(W)x430mm(D) Can be mounted on either the right or left side. |

| RTF-23 for RTF-1310, RTF-1250, RTF-1225 and RTF-1210 | 420mm(W)x430mm(D) Can be mounted on either the right or left side. |

RTF規格表

| RTF-1350 | RTF-1325 | RTF-1310 | RTF-1250 | RTF-1225 | RTF-1210 | |

|---|---|---|---|---|---|---|

| Loading System | Closed-loop micro-computer controlled digital servo mechanism | |||||

| Maximum Capacity | 50kN | 25kN | 10kN | 5kN | 2.5kN | 1kN |

| Test Width | 590mm | 420mm | ||||

| Crosshead Stroke | 1000mm | 1100mm | ||||

| Effective Stroke | 618mm | 580mm | 690mm | 665mm | 775mm | |

| Crosshead Speed | 0.0005 - 1000mm/min | |||||

| Speed Accuracy | ±0.1% | |||||

| Crosshead Return Speed | 1000mm/min or 500mm/min | |||||

| Load Measurement Accuracy | ±0.5% of indicated value | |||||

| Load Range | Full Auto Range ( max. 128 times) | |||||

| Load Calibration | One touch auto-calibration | |||||

| Safety Function for overloading | Provided | |||||

| Sample Break Detection | Provided | |||||

| Stroke Limiter | 2 points Upper/Lower | |||||

| Sampling speed | 1msec | |||||

| Weight | 330kg | 110kg | ||||

RTG規格表

| RTG-1310 | RTG-1250 | RTG-1225 | RTG-1210 | |

|---|---|---|---|---|

| Loading System | Closed-loop micro-computer controlled digital servo mechanism | |||

| Maximum Capacity | 10kN | 5kN | 2.5kN | 1kN |

| Test Width | 420mm | |||

| Crosshead Stroke | 1100mm | |||

| Effective Stroke | 580mm | 690mm | 665mm | 775mm |

| Crosshead Speed | 0.05 - 1000mm/min | |||

| Speed Accuracy | ±0.2% | |||

| Crosshead Return Speed | 1000mm/min or 500mm/min | |||

| Load Measurement Accuracy | ±1% of indicated value | |||

| Load Range | Full Auto Range ( max. 128 times) | |||

| Load Calibration | One touch auto-calibration | |||

| Safety Function for overloading | Provided | |||

| Sample Break Detection | Provided | |||

| Stroke Limiter | 2 points Upper/Lower | |||

| Sampling speed | 1msec | |||

| Weight | 100kg | |||