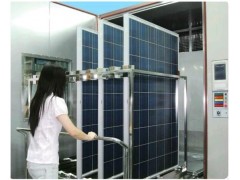

Product performance:

PV module test chamber / PV modules wet frozen cycling chamber is used primarily with the photovoltaic industry, and the necessary test equipment for the solar industry, is used to test photovoltaic modules, monocrystalline module Crystalline silicon terrestrial photovoltaic components, the ground at high temperature, low temperature thin film PV modules, PV modules, alternating hot and humid degrees or the constant change of the temperature of the test environment parameters and performance parameters; Damp heat test the temperature of the environment change and Performance. applies to schools, factories, military, research-bit, and other units.

Test Method satisfy:

This product meet GB/T19394.-2003 test; of GB/T9535.-1998 trial; GB/T6492-1986 GB/T6494, GB/T6497 SJ/T2196,; IEC61345-1998; to IEC 61646, IEC61215 national standards, as well as other the requirements of the relevant standards. Strictly designed and manufactured according to GB 10592-89 "High and low temperature Test chamber technical conditions", GB10586-89 "heat chamber technical conditions", at the same time meet the IEC61215-2005 temperature, and a variety of high and low temperature alternating hot and humid environment can be hot and humid the corresponding standard parameter trials.

Technical parameters:

Model: CRS-CTH1500

Studio Size: 1000 * 1000 * 1500 units of D * W * H: MM

Model: CRS-CTH3000

Studio Size: D * W * H 1200 * 1200 * 2000

Temperature range: -40 ℃ ~ 100 ℃

2 Humidity range: 30% to 98% of R • H (40 to 90 ° C) (Controllability)

3, the temperature fluctuation: ≤ ± 0.5 ℃

4, the temperature deviation: ≤ ± 2 ℃

5, humidity Deviation: +2 -3% R • H

6, the time range: 0 ~ 9999H adjustable

7 Power: ACø3 380V 50Hz

Meet trials indicators:

Thermal cycle test:

PV modules in the wind speed of not less than 2m • S-1 test space temperature cycles between -40 ℃ ± 2 ℃ and 85 ℃ ± 2 ℃

Wet --- cold (frozen) test:

PV modules into the environmental test chamber at room temperature, the completion of 10 cycles. The maximum and minimum temperatures should be less than the set value ± 2 ℃ above ambient temperature, relative humidity should be maintained within the setting ± 5% R • H.

Structure

1, the shell is made of high quality A3 steel (t = 1.2mm) CNC machining, surface spray treatment, clean and beautiful;

2, insulation material: high density fiberglass insulation thickness of 100mm;

Mixing system: the long axis of the fan motor, resistant to high temperature stainless steel multi-blade impeller, the intensity of convection vertical diffusion cycle;

Heating system

1, the to using the far infrared nickel alloy high-speed heating (3KW × 3) electric heater;

2, the high temperature is completely independent systems, does not affect the low temperature test, high temperature test and the hot and humid;

Humidification system

External boiler steam humidifier;

2, with automatic compensation of the water level, water alarm system;

3, far infrared stainless steel heating (0.75KW × 4) high-speed electric heater;

4, humidity control P. I. D + S. S. R, the system of co-channel coordination control.

Control system

Temperature and humidity control instruments using the full import of the large screen (5.7-inch LED LCD display) screen operations simple and easy programming without key input, screen directly touch option. Accuracy: 0.1 ℃ (display range)

Resolution: ± 0.1 ℃;

Refrigeration systems

l compressors: full closure Hermetic Taikang or semi-closed Copeland, Germany;

l cooling mode: Dual Complex Diego refrigeration; Condensation: forced air-cooled; circulating water cooling

l refrigerant: R23; R404A

l filter drier, refrigerant flow window repair valves, oil separators, solenoid valve, liquid storage cylinder using imported original parts;

Protection system

Equipment for the protection of the functions are perfect.

Specific product size and customer requirements to design and manufacture.