It is suitable for testing automotive interior materials, plastics, rubber, leather, coated fabrics, coating materials, composite materials, paints, inks, soft metals and other industries. It is widely used in product quality control, new product R & D performance verification, testing agency testing and other fields.

Product details

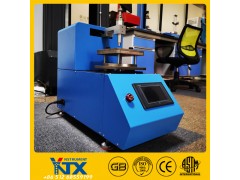

The scratch resistance tester, through the relative movement of the contact between the scratch head and the surface of the material, finally evaluates the sensory grade of the scratch, the color difference change of the scratched area and the non scratched area after the scratch, or the peeling off of the sample surface coating after the adhesive tape treatment after the scratch, is a common test instrument for the evaluation of the scratch resistance of the material surface and the coating.

Product features:

1. The replaceable scraping head can meet the requirements of various test standards. The conical scraping head, square scraping head and needle scraping head can be replaced at will, and the customized service of special scraping head can be provided according to the use requirements.

2. Each test pressurization weight is universal, and the pressure can be easily confirmed; multiple parameters such as speed, stroke, hundred grid spacing can be adjusted as required.

3. The touch screen operation interface is simple and easy to use, and Chinese and English are optional; the current progress is displayed in real time to facilitate the control of the test process.

Technical parameters:

Test method: 100 grid scratch test

Travel range: 10-100mm

Speed range: 10-200mm / S

Moving space of 100 grid method: 0.5mm-2mm (special scraper finger shall be selected below 2mm)

Scraping pressure: 2n, 3N, 5N, 7n, 8N, 10N, 12n, 15N, 20n (optional)

Scraping head material: stainless steel; tungsten carbide (optional)

Diameter of scraping head: 0.5mm, 0.75mm, 1mm, 3mm, 5mm, 7mm (optional)

Plastic scraper finger (optional): PMMA; diameter 16mm, thickness 1mm, edge radius 0.5mm, hardness shore D85.